Automate the Complex. Deliver the Custom.

Design++ – Software for Design Automation Solutions

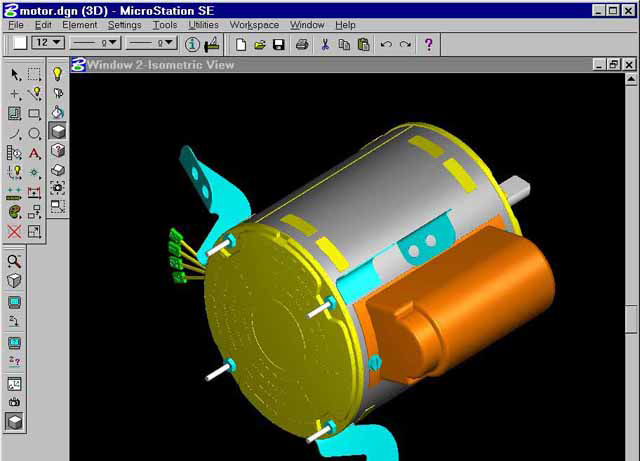

Design++® software-based automation solutions enable corporations to more effectively sell complex systems and products that are Designed-to-Order. They empower the sales force with design-based configurations, proposals and technical drawings, reduce cost by automatic re-use of design rules and best practices in the design for manufacturing, minimize subsequent rework by ensuring feasible designs and, most importantly, build customer loyalty by increasing responsiveness both for initial proposals and subsequent change requests.

Design++® software-based automation solutions enable corporations to more effectively sell complex systems and products that are Designed-to-Order. They empower the sales force with design-based configurations, proposals and technical drawings, reduce cost by automatic re-use of design rules and best practices in the design for manufacturing, minimize subsequent rework by ensuring feasible designs and, most importantly, build customer loyalty by increasing responsiveness both for initial proposals and subsequent change requests.

Design++ lets in-house product experts rapidly deploy solutions that have demonstrable and compelling ROI through accelerated sales execution, shorter delivery schedules and reduced cost of ill-defined orders.

Design++ makes instant design-to-order a reality. In the same way that spreadsheets simplified financial modeling Design++ simplifies the creation of engineering/design automation solutions that enable instant generation of design-based sales proposals for Design-to-Order products and systems.

The 10:1+ productivity improvements demonstrated in real design-to-order automation projects meet the definition of the “Silver Bullet” as described by Frederick Brooks in his book The Mythical Man-Month. If rapid deployment is of concern then this is the tool for you both in small and large projects.

How Design++ Works

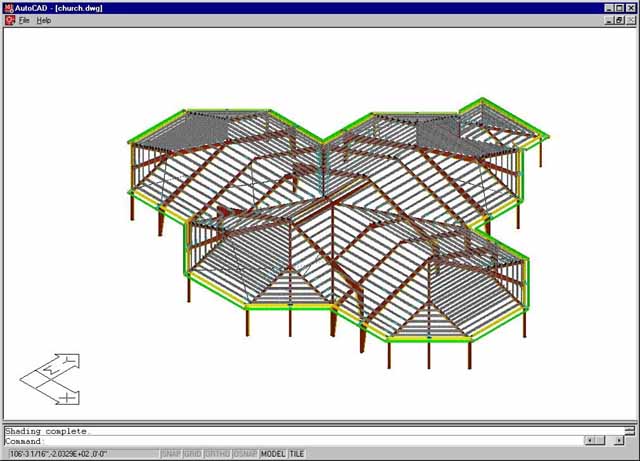

Quality

Consistent design using a company’s most experienced expertise ensures highest quality products. This is what Design++ provides a manufacturing company as, e.g., Robertson Ceco Corporation found:

Our goal was not simply to make drafting more efficient, we wanted to take what our designers new about our products and about detailing and use it consistently across all building complexity. We wanted to achieve senior designer results regardless of the tenure of the person involved in the project.

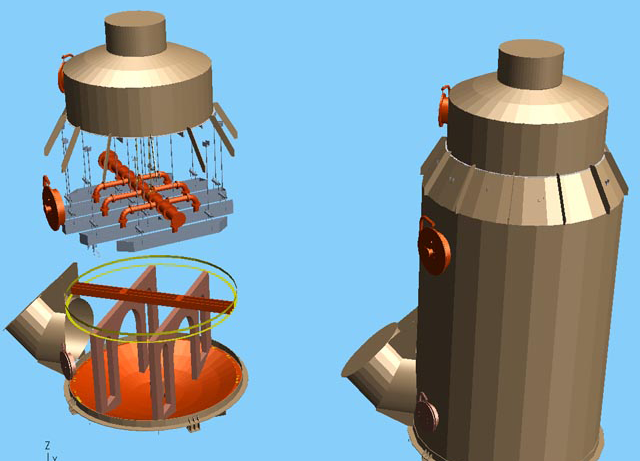

Knowledge Retention

Knowledge is a Company’s most significant asset but fleeting, existing mainly with the employees of the company. Design++ provides the means to capture this knowledge for reuse:

Robertson Ceco Corporation found in Design++ a system which: “… answered the challenge of retaining the knowledge of design personnel, “encapsulating their knowledge in a form that could be perpetuated and easily maintained in the future as our product evolves to meet market demand.”