P&ID Configurator

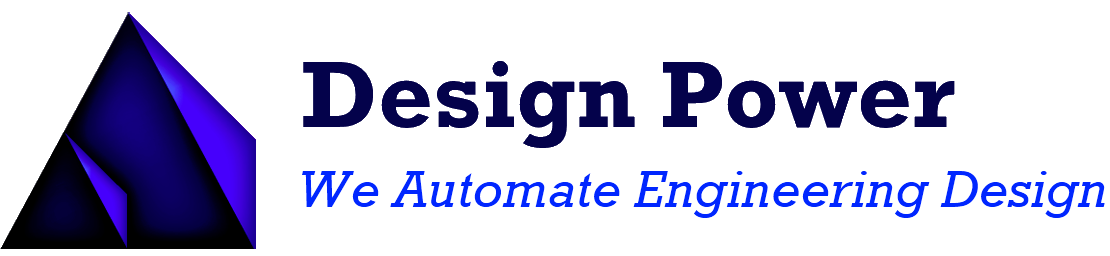

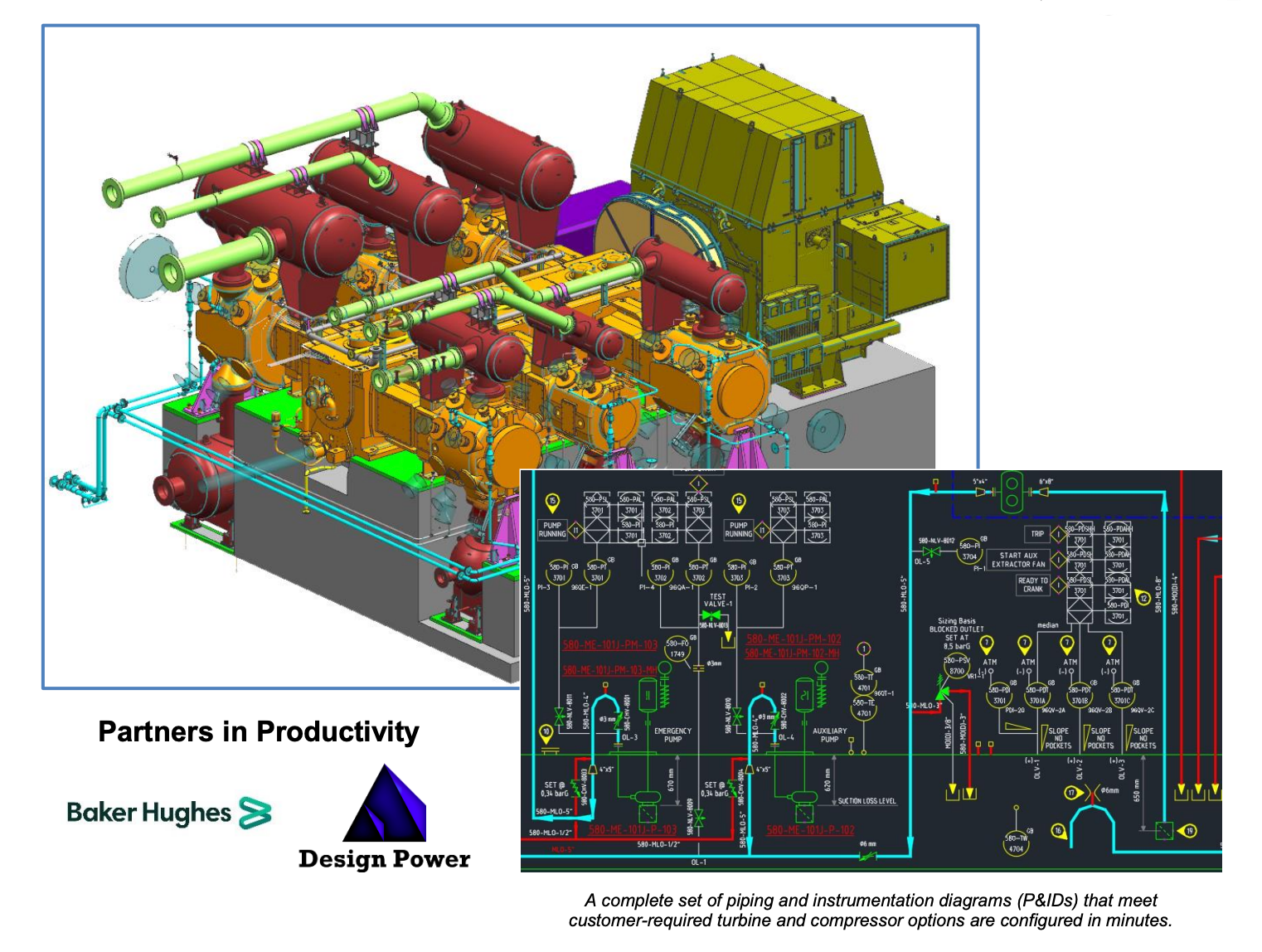

Baker Hughes provides highly customized compressors and turbines.

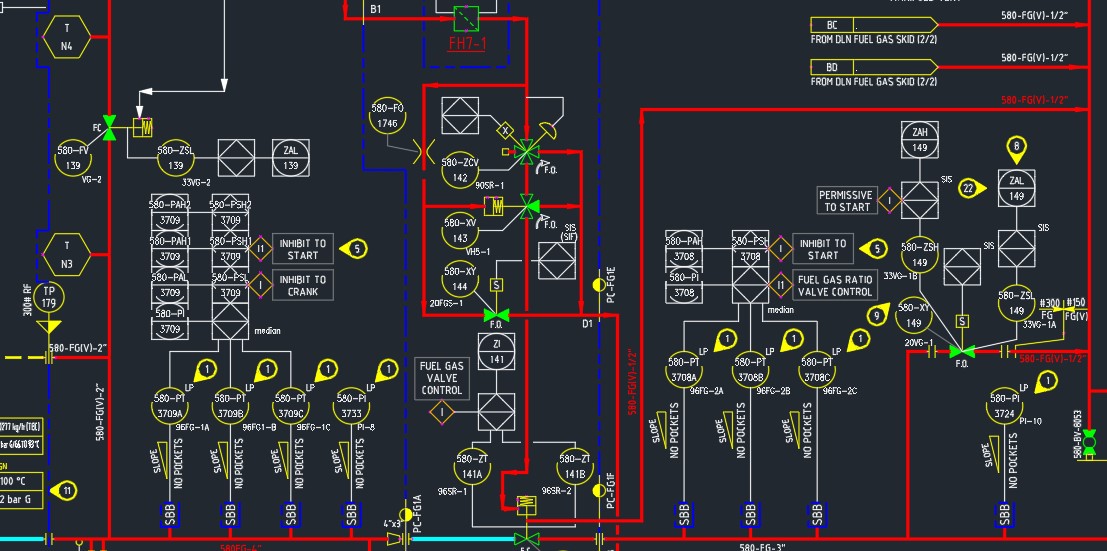

Highly customized compressors and turbines require extensive and detailed drawings and schematics to support sales, manufacturing, installation, and operations. A single compressor, including all auxiliary systems like lubrication, hydraulics, and cooling, may demand over 60 P&ID drawings, each taking up to four hours to create manually.

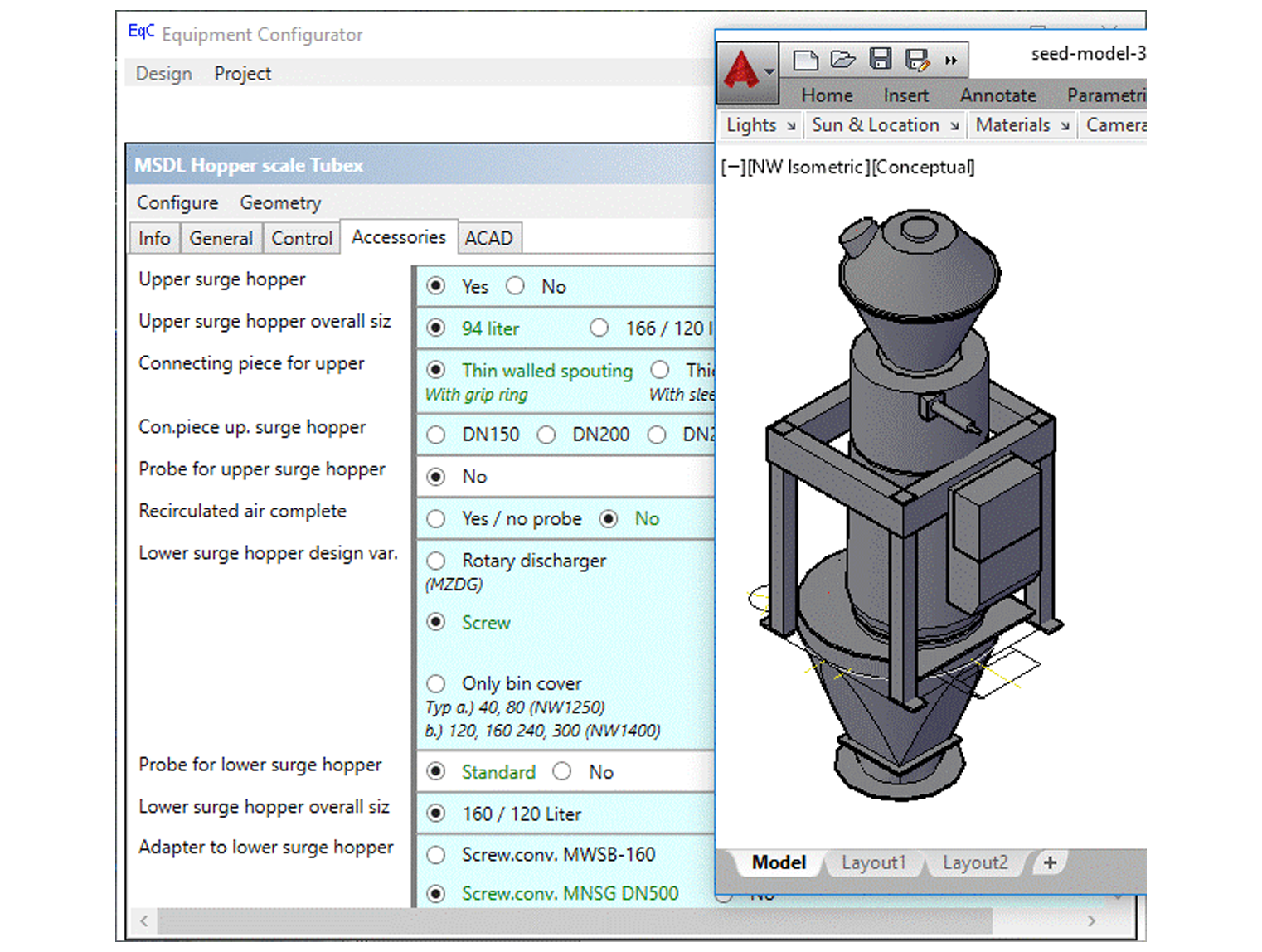

To improve efficiency, Baker Hughes sought a solution to streamline the process, minimizing unnecessary revisions and better accommodating customer modifications. This led to the creation of the P&ID Configurator, an automated tool built on Design Power’s Design++ technology and DrawingWise solution framework, which now generates all auxiliary system P&IDs for Baker Hughes.

At the heart of the P&ID Configurator is the concept of SuperDrawings. These contain all the necessary logic and CAD symbols to produce a complete set of P&IDs for any equipment and control options. When a new P&ID set is required, the configurator quickly assembles and connects all CAD symbols based on base equipment and customer-specific options. What used to take up to 30 days is now completed in just 20 minutes.

Today, over 500 Baker Hughes engineers worldwide rely on the cloud-based P&ID Configurator for their daily operations.